The cordless drill is an essential tool for the do-it-yourselfer. It offers ease of use, convenience and flexibility while also eliminating the risks associated with a corded drill. Yet, venture into the tool department of your local hardware store or home improvement superstore, and you’ll see a multitude of cordless drills from which to choose. While your first inclination may be to buy the biggest one you can afford, you may not be making the best decision.

This cordless drill buyer’s guide will help you determine exactly what type of drill will deliver the results you need and help you avoid overpaying for capabilities you’ll never use.

Contents:

Overview

According to Wikipedia, a drill or drilling machine is a tool primarily used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driver, depending on application, secured by a chuck. Some powered drills also include a hammer function.

Drills vary widely in speed, power, and size. They are characteristically corded electrically driven devices, with hand-operated types dramatically decreasing in popularity and cordless battery-powered ones proliferating.

Drills are commonly used in woodworking, metalworking, construction, machine tool fabrication, construction and utility projects. Specially designed versions are made for medicine, space, and miniature applications.

1. Cordless Drill Types

There are essentially four different types of cordless drills, each designed to perform a specific range of jobs:

- Cordless screwdrivers

- Basic cordless drills

- Cordless impact drivers

- Cordless hammer drills

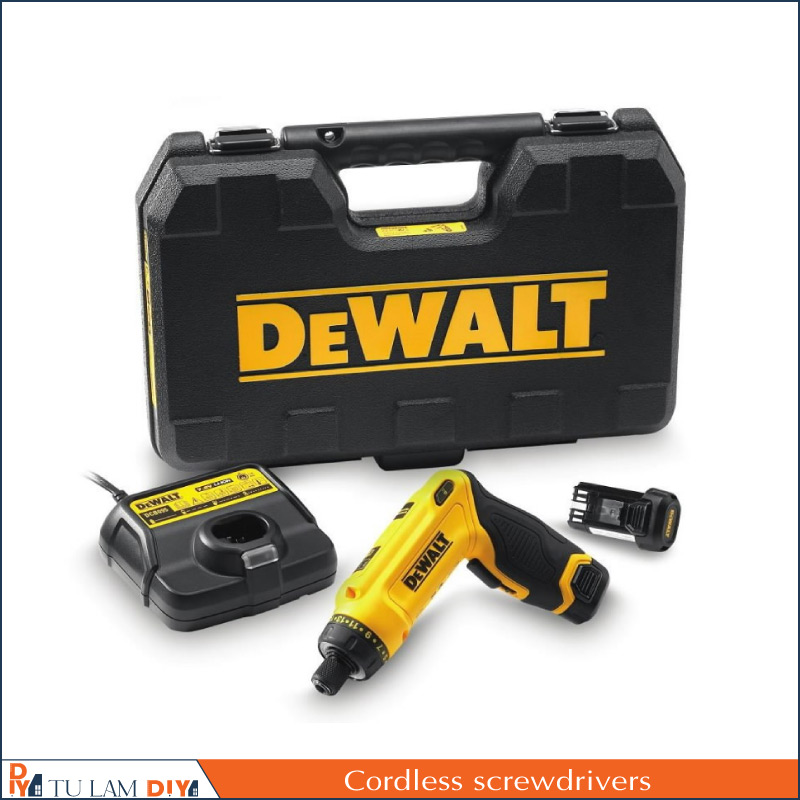

Cordless screwdrivers

A cordless screwdriver is an automated screwdriver that falls under the category of cordless drills. It has the least amount of power in the drill category, as its primary function is only to drive screws for small, one-time projects like hanging a picture or a shelf. Cordless screwdrivers typically range from 2.4 to 10.8 volts.

Basic Cordless Drills

Basic cordless drills fit the needs of most do-it-yourselfers quite well, as these tools offer more power and capabilities than a standard cordless screwdriver. A basic cordless drill features an adjustable clutch to maximize the drill’s spinning power and an adjustable chuck so it can accommodate both drill bits and individual screwdriver bits. These two features make it a versatile tool that is capable of drilling holes in wood or light metals as well as driving and removing screws. Typical basic cordless drills range from 9.6 to 18 volts.

Cordless Impact Drivers

A cordless impact driver is essentially the same thing as a basic cordless drill but with one exception-when the drill senses resistance, it automatically increases the torque to prevent the bit from slipping out of the screw head. This feature helps reduce the chances of stripping screws and ruining bits and also eliminates the need for a pilot hole.

Cordless impact drivers are not as effective as basic cordless drills at drilling holes, but they are more suitable for use on large projects like building a deck, shed or add-on. Impact drivers typically range between 14.4 and 20 volts.

Cordless Hammer Drills

Cordless hammer drills are the most powerful family of cordless drill because their main purpose is to drill through hard surfaces like brick or concrete. A cordless hammer drill features an adjustable clutch, as a basic drill does, so it can be used as such for general purposes, but the final setting is designed for hammer drill use only. In this mode, the drill bit punches in and out while simultaneously spinning.

When the hammer drill is used, special bits are required. Because of the required extra strength, cordless hammer drills are the heaviest of all the cordless drill options, and they typically range between 18 and 36 volts.

2. Cordless Drill Considerations

When determining the type of cordless drill that will best suit your needs, consider the following:

- Chuck size

- Battery voltage

- Battery types and chargers

- Torque

- Special features and accessories

Chuck size

Cordless drills typically feature one of two different-sized chucks, 3/8-inch or half-inch. These measurements refer to the largest drill bit shank the chuck can accept. The do-it-yourselfer will rarely require the half-inch shank drill bits, so a drill with a 3/8-inch chuck will generally suffice.

Cordless drills with 3/8-inch chucks are usually less expensive than drills featuring half-inch chucks. And, although they can’t accept shanks larger than 3/8-inch, they can still fit bits that are capable of drilling holes larger than that size.

Battery voltage

Most do-it-yourselfers can get along quite well with 10.8- to 12-volt cordless drills if their only requirements are typical home repairs and minor construction tasks. As expected, the higher the voltage, the greater the torque, or power. Of course, having a strong battery doesn’t mean much if you are constantly running out of juice.

To help you get the most out of your battery, consider its amp-hours (Ah) rating. This will indicate how long the battery will last. For some, a lower voltage battery with a higher amp-hour rating is a better choice than a higher voltage battery with a lower amp-hour rating.

Battery types and chargers

The type of battery that comes with your cordless drill often determines how heavy or light the drill will ultimately be. While many conventional cordless drills come with nickel-cadmium (NiCd) batteries, newer, greener alternatives are available. Lithium-ion (Li-Ion) and nickel-metal-hydride (NiMH) batteries are available, and these types offer increased power and run time while weighing less than NiCd batteries.

Li-Ion and NiMH batteries are also better for the environment, as they do not contain the toxic material cadmium, which over time can find its way into groundwater if the NiCd battery is thrown in the trash and not recycled properly. Battery type is usually a determining factor in the price of the cordless drill, and drills that feature new-tech batteries typically cost more than their NiCd counterparts.

The battery charger that comes with your cordless drill is another thing to consider. There are typically two types of battery chargers-rapid chargers and slow chargers. Again, depending on your needs, the battery charger can make or break your purchasing decision. Rapid chargers can usually produce a fully charged battery in 15 minutes or under, while slow chargers can often take a few hours to replenish the voltage.

Smart chargers are also available. This type of charger has an indicator that tells the user how far along the recharging process is and automatically turns itself off to prevent overcharging the battery, which can damage it.

Torque

Torque is the measurement of twisting force the drill applies when in use, or in layman’s terms, it’s how powerful the drill is. Typically, the higher the voltage, the higher the torque, but you will notice that torque does vary between different models featuring the same voltage. Torque is often affected by the physical makeup of the drill’s motor, so objective tests are usually a better representation of how powerful a drill can be.

Accessories

Accessories are typically bells and whistles that are nice to have but not entirely necessary in order to get the job done. These can include the following:

- Built-in LED lights

- Built-in level

- Built-in bit storage areas

- Magnetic trays

- Auxiliary handle

- Pressure sensitive triggers

- Single-sleeve keyless chuck

- Carrying case

Of all the accessories, the one that is truly recommended is the auxiliary handle for the cordless hammer drill. This handle makes it easier to balance the drill while boring through a solid surface.